sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unité | Valeur |

|---|---|---|

| UNITÉ D'INJECTION | ||

| Volume de tir | cm3 | 1423 |

| Poids du tir | g | 1295 |

| Vitesse de tir | mm/s | 585 |

| Diamètre de la vis | mm | 75 |

| Pression d'injection | MPa | 137 |

| Rapport L:D de vis | -- | 18.7 |

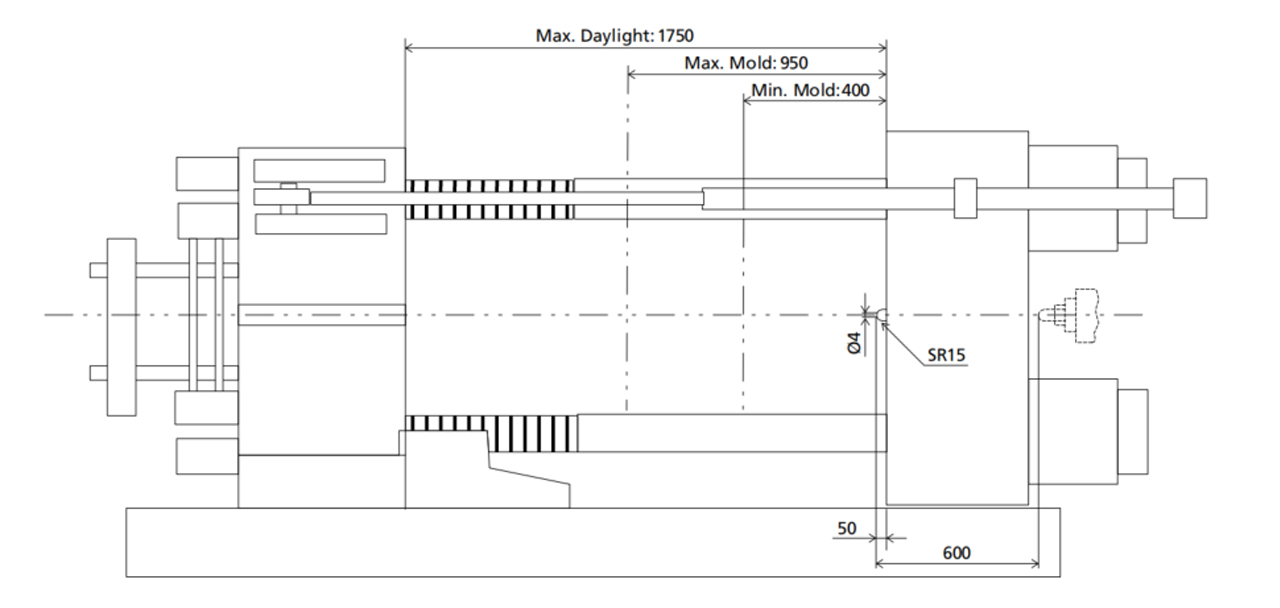

| UNITÉ DE SERRAGE | ||

| Force de serrage | kN | 6500 |

| Coup d'ouverture | mm | 1350 |

| Espace entre les barres de liaison | mm x mm | 1040 x 910 |

| Épaisseur du moule(min) | mm | 400 |

| Épaisseur du moule(max) | mm | 950 |

| Course d'éjection hydraulique | mm | 250 |

| Force d'éjection hydraulique | kN | 110 |

| UNITÉ DE PUISSANCE | ||

| Moteur de pompe | kW | 55 |

| Capacité de chauffage | kW | 33 |

| GÉNÉRAL | ||

| Capacité du réservoir d'huile | L | 450 |

Clamping Unit

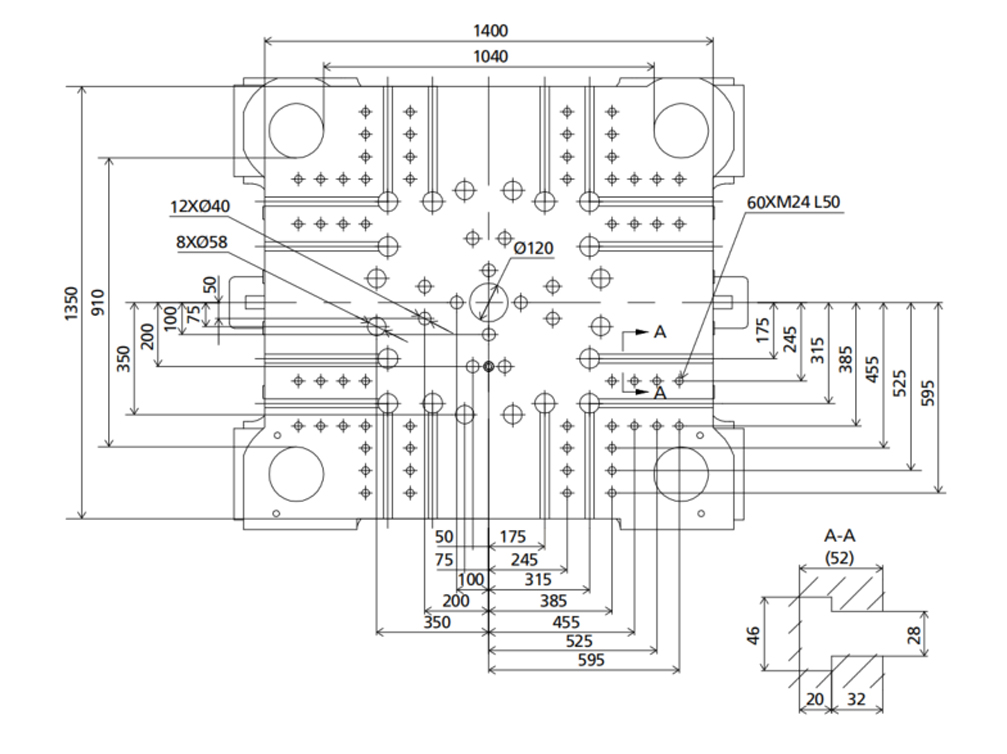

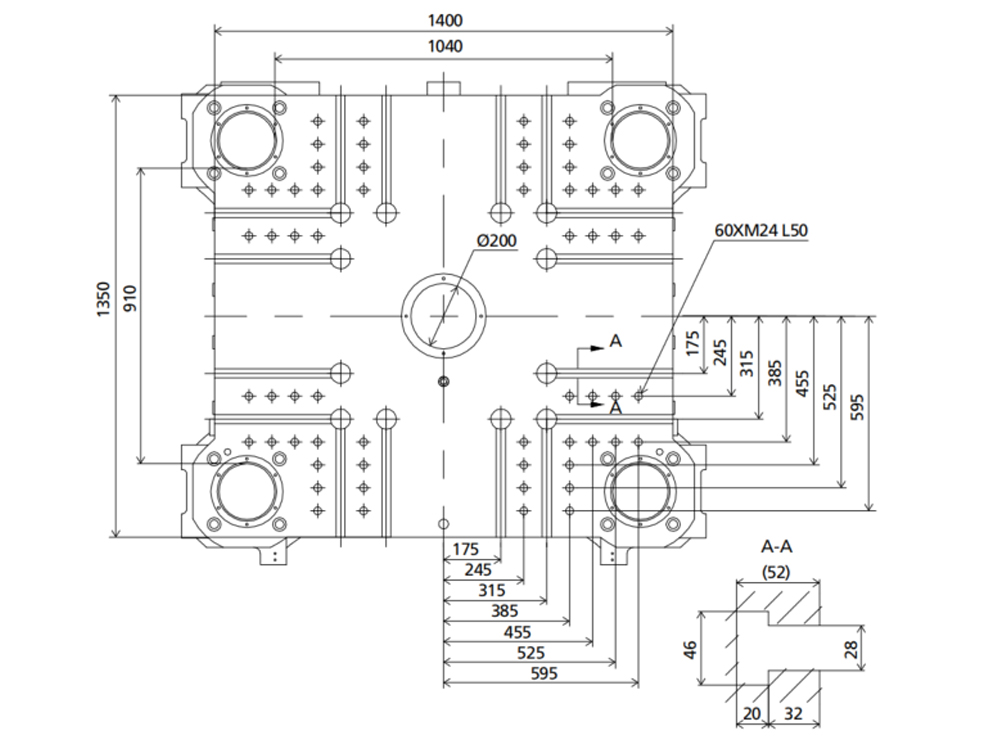

Platen Dimensions

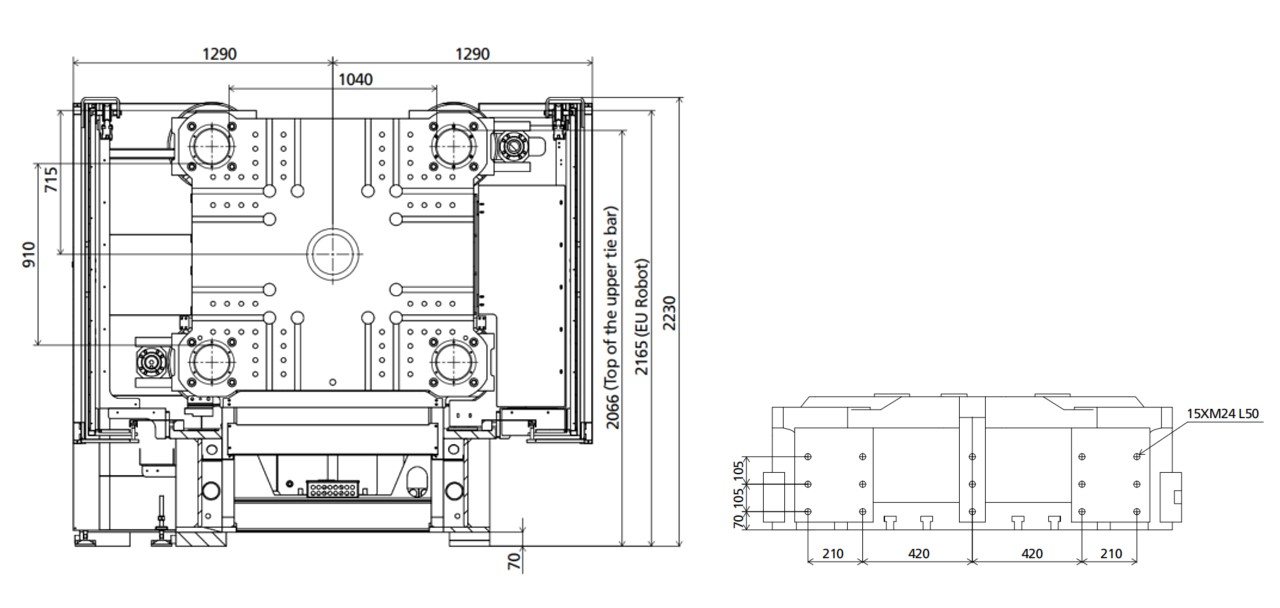

Robot

Front View

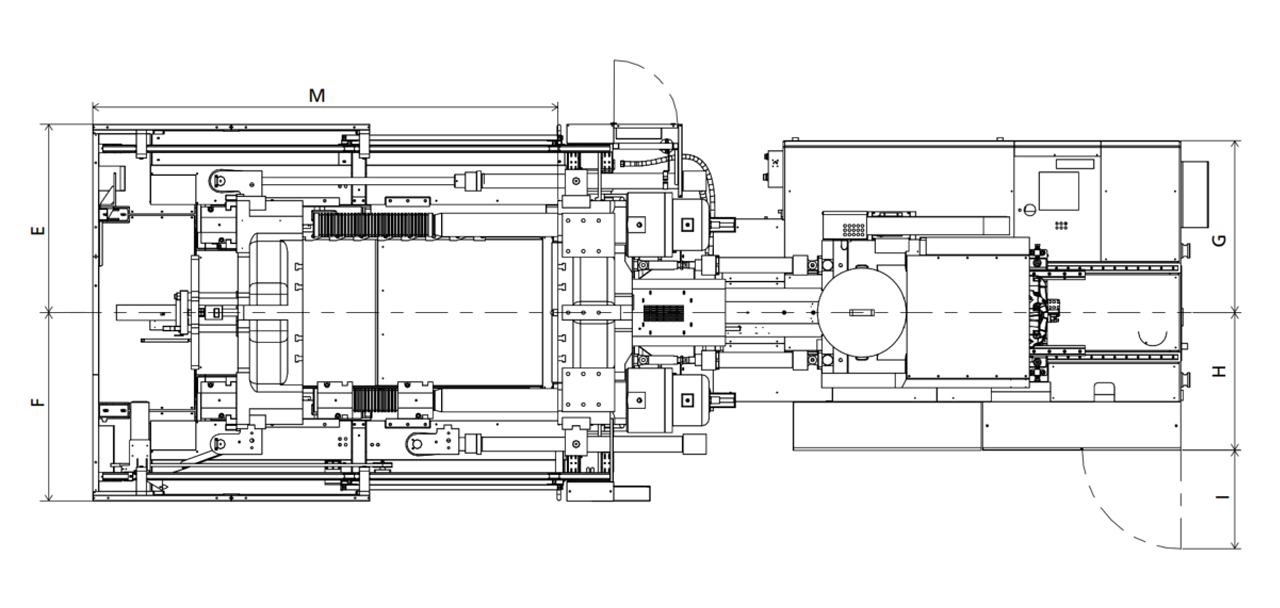

Top View

Side View

| # | Value |

|---|---|

| A | 2165 mm |

| B | 2066 mm |

| C | 2327 mm |

| D | 2200 mm |

| E | 1290 mm |

| F | 1290 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3746 mm |

| K | 3707 mm |

| M | 3191 mm |

| N | 1560 |

What's the Budget of a Turn-key 8 Cavities 700ml Cups Side Entry IML Solution?

"Milk Tea", a beverage with a mixture of the tea, fruit juice, corn, peanut and maybe something else which will totally out of your imagination is getting more and more popular in China and South-East Asia. It's easy to find a new tea store while working in the street of the main city of China in a couple of weeks with new flavours. Some of them like CHAGEE is not only popular in China, but also in Malaysia, Thailand, Vietnam. Which make the production of the IML cups for the take away "Milk Tea" a business of billions of dollars.

For a side entry IML system for the production of 700ml beverage cups, you'll need:

With the first side entry IML system put on market in 2009, SWITEK has cooperating with the major manufacturer of high speed injection molding machine and the mold making company in China to provide you with a price smart solution of IML for the cups. With a turn-key solution you'll have the injection molding machine, the mold and the IML robots well tested together before delivery to ensure the system received is ready to work and reduce the start up cost.

Technologie IML Express

E-mail: sales@switek.biz

Contacter le blogueur

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China