sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| 説明 | ユニット | 価値 |

|---|---|---|

| 射出ユニット | ||

| ショット量 | cm3 | 2497 |

| ショット重量 | g | 2272 |

| ショットスピード | mm/s | 593 |

| ネジ径 | mm | 85 |

| 射出圧力 | MPa | 160 |

| ねじの長さ:奥行きの比 | -- | 20.7 |

| クランピングユニット | ||

| 締付力 | kN | 5500 |

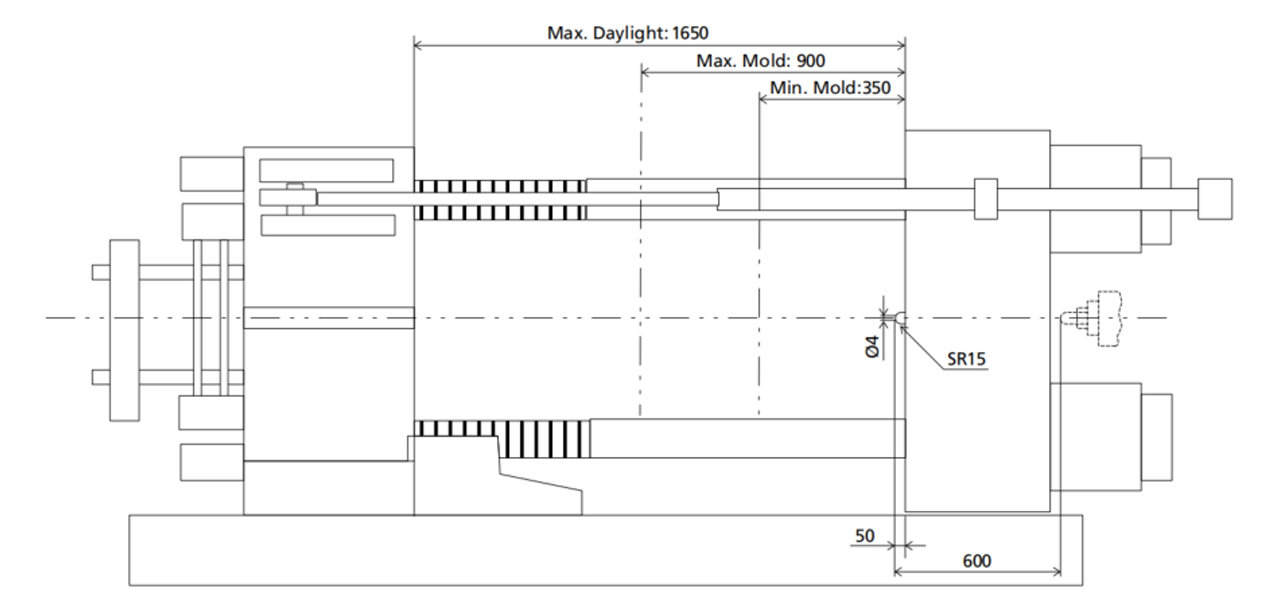

| オープニングストローク | mm | 1300 |

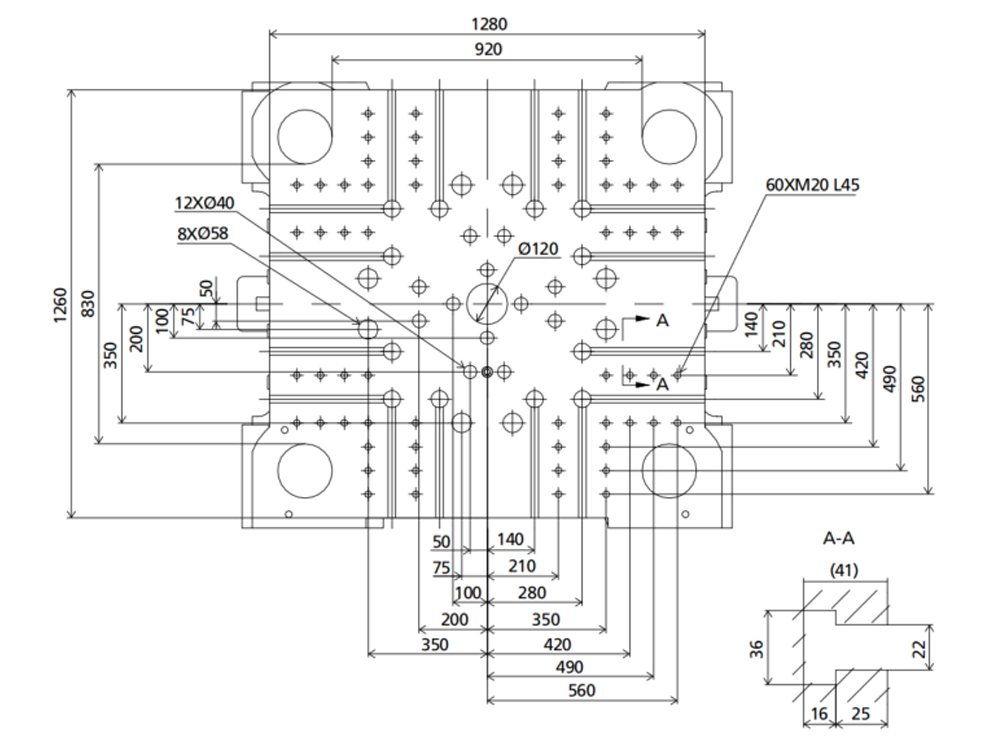

| タイバー間のスペース | mm x mm | 920 x 830 |

| 金型の厚さ(min) | mm | 350 |

| 金型の厚さ(max) | mm | 900 |

| 油圧突き出しストローク | mm | 250 |

| 油圧による突き出し力 | kN | 110 |

| パワーユニット | ||

| ポンプモーター | kW | 65 |

| 暖房能力 | kW | 48 |

| 一般的な | ||

| オイルタンク容量 | L | 600 |

Clamping Unit

Platen Dimensions

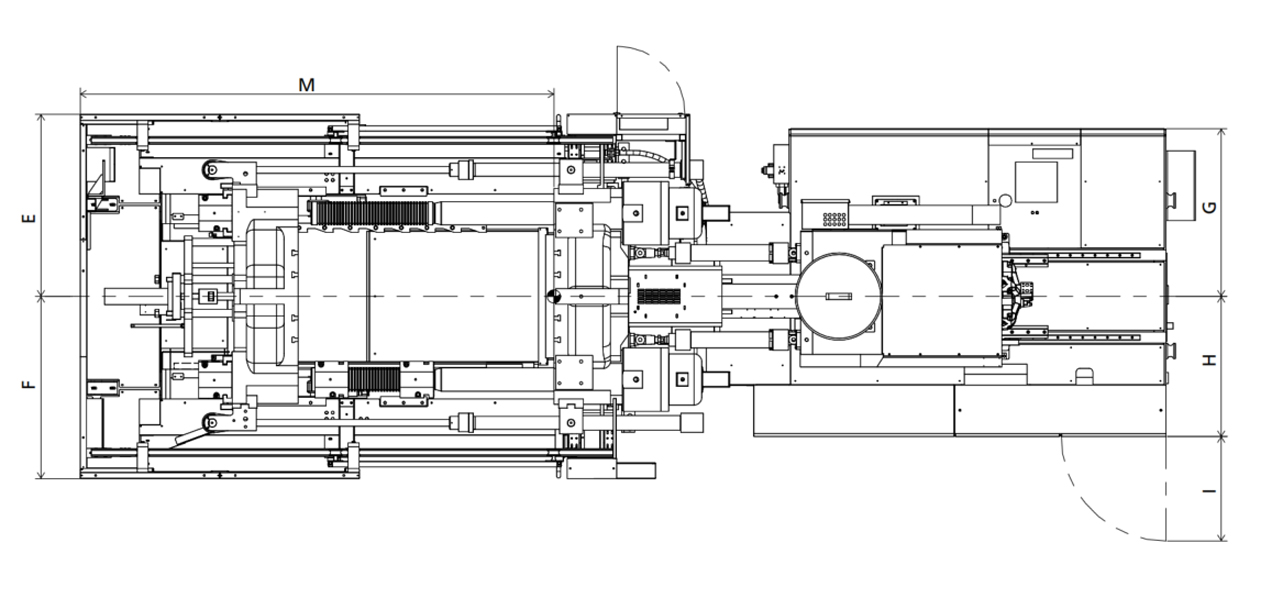

Robot

Front View

Top View

Side View

| # | Value |

|---|---|

| A | 2110 mm |

| B | 2016 mm |

| C | 2671 mm |

| D | 2250 mm |

| E | 1175 mm |

| F | 1175 |

| G | 1177 mm |

| H | 943 mm |

| I | 675 mm |

| J | 3581 mm |

| K | 4019 mm |

| M | 3056 mm |

| N | 1400 |

Email: sales06@switek.biz

射出自動化ニュース&エクスプレス

Chinaplas 2024はまもなくオープンします、準備はできていますか?

LK、Kフェア2016でペール缶サイドエントリーIMLソリューションを搭載したFORZA 2プラテン射出成形機を展示

K-2022、Zhafir が Jenius シリーズ ハイブリッド射出成形機を展示

Chinaplas 2024 -- VALMO が Acmeplas の IML ロボットを備えた 8 キャビティ カップ IML ソリューションを展示

Chinaplas 2024 -- LK ブース #4.1C52 で新しい全電動射出成形機を展示

Chinaplas 2024 -- WELLTEC Machinery はブース #5.1D42 で新しい全電動射出成形機を展示します

WETECは、2.9秒のサイクルタイムで4つのキャビティカップのIMLソリューションを展示しました

BOLE 新型 EKH シリーズ射出成形機が自動車部品生産用にタイに設置

Chinaplas 2024 -- HWAMDA (HMD) ブース #5.1D52 で新しい高速射出成形機を展示

K-2022、Yizumiが高速全電動射出成形機PAC250Eを搭載したターンキーIMLソリューションを展示

ブロガーに連絡する

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China

HuangYanZheng©Copy Right